centrifugal pump|centrifugal pump vs positive displacement : import Centrifugal Pump Casing. The centrifugal pump casing seals the pump inside the atmosphere. It is an air-tight boundary that retains the pressure and converts the impeller velocity into a stable flow. In centrifugal pumps, the casing surrounds the pump rotor.The casing converts the velocity head into the pressure head. autoclave bags (no biohazard symbol) should be used for non-pathogenic biological material like E. coli. Cultures of non-pathogenic organisms must be destroyed through autoclaving or .

{plog:ftitle_list}

DryShield Autoclavable Mouthpieces for dental offices have built-in tongue and .

Learn what a centrifugal pump is, how it works, and what parts it consists of. Find out how to select, size, and install a centrifugal pump for different applications.Centrifugal Pump Casing. The centrifugal pump casing seals the pump inside the atmosphere. It is an air-tight boundary that retains the pressure and converts the impeller velocity into a stable flow. In centrifugal pumps, the casing surrounds the pump rotor.The casing converts the velocity head into the pressure head.When it comes to moving fluids efficiently, one piece of equipment often reigns supreme: the centrifugal pump.Indeed, seen across many applications from domestic water supplies to oil and gas operations, the unsung hero behind numerous .

How does a centrifugal pump work? A. A centrifugal pump is a type of rotodynamic pump that uses bladed impellers with essentially a radial outlet to transfer rotational mechanical energy to the fluid primarily by increasing the .

Factors That Impact Centrifugal Pump Working. Suction Pressure – If pressure at pump suction is less than required, it may lead to cavitation. Cavitation will severely impact pump performance and can damage the impeller permanently.Pump Laws. Centrifugal pumps generally obey what are known as the pump laws. These laws state that the flow rate or capacity is directly proportional to the pump speed; the discharge head is directly proportional to the square of the pump speed; and the power required by the pump motor is directly proportional to the cube of the pump speed.

This article explains how centrifugal pumps work. Centrifugal pumps are used to transfer fluids and other materials in a wide variety of applications. This article is a helpful primer on the how's and whys of centrifugal pumps, and is useful if you're interested in learning more about this type of pump.

A pump is a device that uses to transfer different incompressible fluids. These are used all over the world for different industries. There are many types of pumps and the centrifugal pump is one of them. This article mainly explains the centrifugal pump working, types, parts, applications, advantages, and disadvantages.Centrifugal pumps represent an integral part of our life today. They are primarily used for moving liquids from one place to another using an energy conversion process.In 1689 the physicist Denis Papin invented the centrifugal pump, and today centrifugal pumps are the world’s most commonly used pumps. The centrifugal pump is built on a

A centrifugal pump converts input power to kinetic energy by accelerating liquid in a revolving device - an impeller. The most common is the volute pump - where fluid enters the pump through the eye of the impeller which rotates at high speed.The most commonly used as well as the most popular pumps are centrifugal pumps, which are mainly used for transferring the liquids. These pumps can be inbuilt with a revolving impeller for transferring water otherwise fluids with the help of centrifugal force from one place to another within several industries like municipal, plants for power generation, agriculture, industrial, . What are the main features of a centrifugal pump? There are two main pump families: centrifugal pumps and displacement pumps. Compared to the latter, centrifugal pumps are usually specified for higher flow rates and pumping low viscosity liquids down to 0.1 cP.

Centrifugal pumps have a wide range of applications where the pressure increase is caused by centrifugal forces. Radial, axial and mixed flow pumpsCentrifugal pump is a hydraulic machine which converts mechanical energy into hydraulic energy by the use of centrifugal force acting on the fluid. These are the most popular and commonly used type of pumps for the transfer of fluids from low level . Adjustment method and energy consumption of centrifugal pump based on intelligent optimization algorithm. Wei Zhang, . Jie Cai, in Energy Reports, 2022. 1 Introduction. As a general rotating machinery product, the pump is mainly used for the transmission of liquid medium, and it is widely used in various industries such as petrochemical, water supply and .

The majority of industrial pump systems make use of a centrifugal pump. If you have ever contacted a pump supplier, then you would have probably heard the term, “centrifugal pump.” Ever wondered what exactly is the centrifugal pump .A centrifugal pump is a rotary equipment that converts mechanical energy into kinetic energy through centrifugal force on the liquid. Further power generated from the electric motor drives the impeller of the pump, where fluids enter and .

Centrifugal pump, device for moving liquids and gases. The two major parts of the device are the impeller (a wheel with vanes) and the circular pump casing around it. In the most common type, called the volute centrifugal pump, fluid enters the pump at .3. Casing. The casing of the centrifugal pump is a narrow air-tight passage around the impeller. The casing is designed in such a way so that the kinetic energy of the fluid discharged by the impeller gets converted into the pressure energy before the fluid leaves the casing and enters into the discharge tube. Explore the workings of a centrifugal pump through an animated video on YouTube, presented by LearnEngineering. 18. Suction Head:- Vertical height of center line of centrifugal pump above the water surface to the pump from which water to be lifted. Delivery Head:- Vertical distance between center line of the pump and the water surface in the tank to which water is delivered. Static Head:- Sum of suction head and delivery head. Manometric Head:- The head against which a .

Centrifugal pumps are an integral part of industrial processes, playing a pivotal role in the transportation of fluids. They are widely used across various industries, including the water treatment, chemical, petroleum, and wastewater sectors.2. The Most Important Parts of a Pump: Casings & Impellers. The two main parts of every centrifugal pump are the casing and the impeller. This article explains what these parts do and how they work together to convert rotational energy into liquid flow. Working Principle of Centrifugal Pumps. Whenever a certain mass of fluid is rotated by any external source, say an impeller in the case of a centrifugal pump, is thrown away from the central axis of rotation which enables liquid to rise to a higher level.

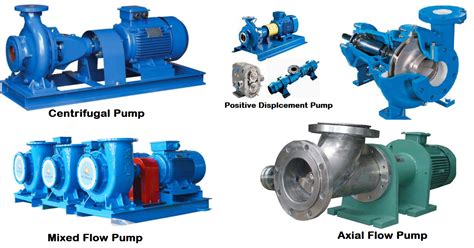

Pumps are generally grouped into two broad categories—positive displacement pumps and dynamic (centrifugal) pumps. Positive displacement pumps use a mechanical means to vary the size of (or move) the fluid chamber to cause the fluid to flow. Centrifugal pump basics. In this tutorial we’re going to be looking at the centrifugal type pump. The centrifugal pump is the most common type of pump used in industry, and it’s used in pretty much every commercial and industrial buildings as well as houses, apartment blocks even ships and some aircraft will have some form of centrifugal pump installed.Centrifugal pumps are pervasive in a multitude of industries and applications due to their ability to efficiently transfer liquids. This includes water supply, sewage and wastewater treatment, petroleum transport, chemical processing, food and beverage production, and more.

types of centrifugal pumps

centrifugal pumps near me

centrifugal pump vs submersible pump

Although it’s possible to sterilize the vast majority of common laboratory loads using one of three basic cycles — gravity, vacuum (or .

centrifugal pump|centrifugal pump vs positive displacement